The magic of 3D printing has never been more accessible than it is today, on September 25, 2025. What was once a futuristic technology confined to industrial labs is now a powerful creative tool sitting on desks in homes, schools, and small businesses across India and the world. The ability to transform a digital design into a tangible, physical object is a game-changer for inventors, artists, engineers, and hobbyists alike. But with this explosion in popularity comes a dizzying array of options.

Choosing your first or next machine can feel overwhelming. That’s why we’ve created this definitive guide. We will demystify the technology, highlight what truly matters when buying a printer, and unveil the best 3D printers of 2025 that cater to every skill level and budget. Let’s turn your brilliant ideas into reality.

Choosing Your Path: FDM vs. Resin 3D Printing

Before looking at specific models, you must understand the two main types of consumer 3D printers. Your choice here will define what you can create.

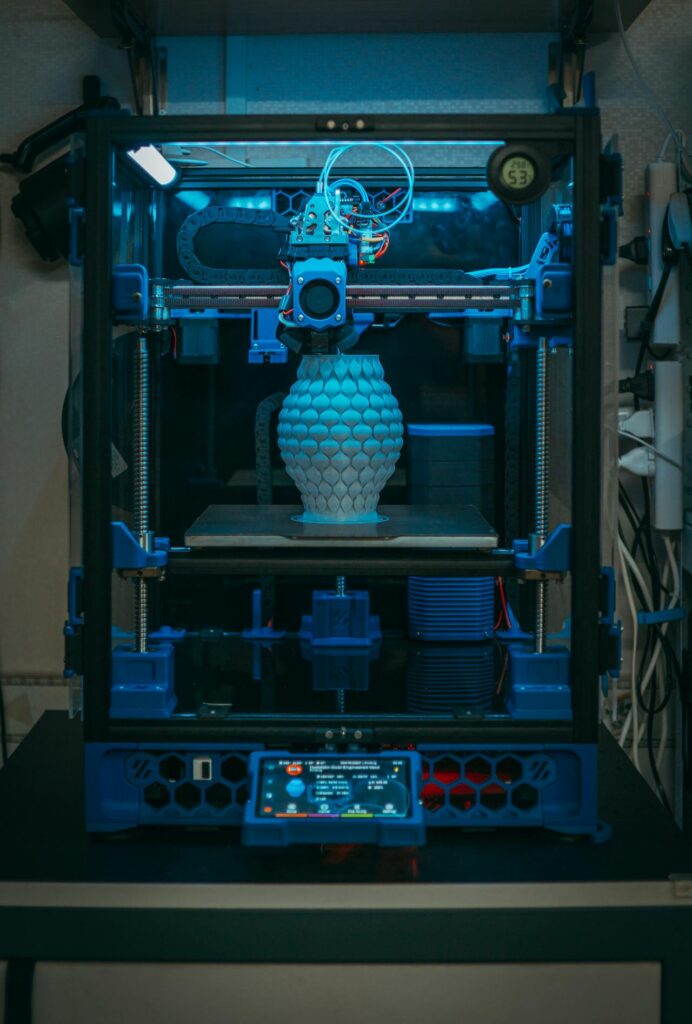

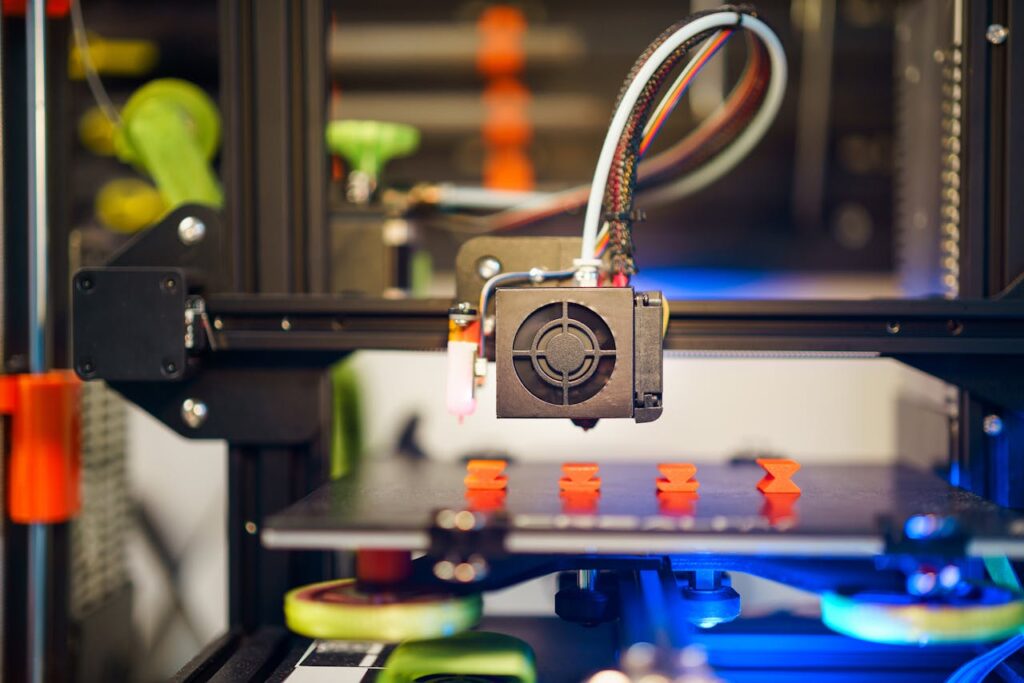

- FDM (Fused Deposition Modeling): This is the most common type of 3D printing. FDM printers work by melting a spool of plastic filament and extruding it through a nozzle, building an object layer by painstaking layer. It’s like a robotic hot glue gun drawing in three dimensions. FDM is fantastic for creating strong, functional parts, large prototypes, and cosplay props. It’s generally more affordable and offers a wider variety of materials (like PLA, PETG, and ABS).

- Resin (SLA/MSLA): Resin printers offer breathtaking detail. They work by using a UV light source to cure liquid photopolymer resin in a vat, layer by layer. This process, known as stereolithography (SLA) or Masked SLA (MSLA), can produce objects with incredibly smooth surfaces and intricate details, far surpassing what FDM can achieve. This makes them the go-to choice for printing things like tabletop miniatures, jewelry molds, and detailed character models.

The bottom line: Choose FDM for strength, size, and functional parts. Choose Resin for stunning, fine-detail work.

4 Critical Factors to Consider Before Buying a 3D Printer

With the basics understood, let’s zero in on what features to look for to find the perfect printer for your needs.

Factor 1: Your Primary Use Case

What do you want to create? Be honest about your goals. If you’re a hobbyist looking to print fun gadgets and household fixes, an easy-to-use FDM printer is a great start. If you’re an engineer needing to create durable prototypes, you’ll need an FDM machine capable of handling engineering-grade materials. If you’re an artist or a jeweler, the detail of a resin printer is non-negotiable. Your application dictates the technology and features you need.

Factor 2: Budget and Total Cost of Ownership

Your investment doesn’t end with the printer itself. Consider the ongoing costs:

- Filament (FDM): A standard 1kg spool of PLA filament costs around ₹1,000 – ₹2,000.

- Resin (Resin): A 1kg bottle of standard resin costs ₹2,000 – ₹4,000.

- Consumables: FDM printers need occasional nozzle replacements. Resin printers require new FEP films for the vat and have a screen with a finite lifespan.

- Safety Gear: For resin printing, nitrile gloves and safety glasses are essential.

Factor 3: Build Volume

Build volume refers to the maximum size of an object you can print, typically measured in millimeters (X x Y x Z). A larger build volume is always tempting, but bigger isn’t always better. Large printers take up more space and can be more challenging to calibrate. Choose a size that realistically fits the objects you plan to make.

Factor 4: Ease of Use and Community Support

For beginners, this is the most important factor. Features like automatic bed leveling, filament run-out sensors, and intuitive touchscreens have become standard on the best 3D printers for beginners in 2025, saving countless hours of frustration. Furthermore, choosing a brand with a large, active online community (like Creality, Prusa, or Bambu Lab) means that tutorials, troubleshooting guides, and user-made upgrades are always just a search away.

The Top 5 Best 3D Printers of 2025: The Definitive List

After extensive market analysis, here are our picks for the most impressive and reliable 3D printers available right now.

1. The Newbie’s Champion: Bambu Lab A1 Mini

Bambu Lab revolutionized the market with its speed and simplicity, and the A1 Mini perfects that formula for beginners. It’s a “just works” machine.

- Type: FDM

- Pros: Incredibly easy setup, class-leading print speed, and fully automatic calibration. The optional AMS Lite unit allows for seamless four-color printing, a feature previously unheard of at this price point.

- Cons: Primarily cloud-based operation might not appeal to everyone. Proprietary parts make some repairs more difficult.

- Best for: Beginners and hobbyists who want to get amazing results right out of the box with minimal tinkering.

2. The Open-Source Workhorse: Prusa i3 MK4

The Prusa i3 has long been the gold standard for serious hobbyists, and the MK4 is the culmination of years of refinement. It’s a printer built by enthusiasts, for enthusiasts.

- Type: FDM

- Pros: Legendary reliability and print quality. Fully open-source hardware and software. A massive, supportive community and excellent documentation. The new load cell sensor provides a perfect, effortless first layer every time.

- Cons: Higher upfront cost compared to competitors. Assembly is required (though a pre-assembled version is available).

- Best for: Tinkerers, serious hobbyists, and print farm operators who value reliability, customisation, and being part of a vibrant ecosystem.

3. The Large-Format Creator: Creality K1 Max

When you need to go big, the Creality K1 Max delivers. It combines a massive build volume with blistering speed, making it a true production machine.

- Type: FDM

- Pros: Huge 300x300x300mm build volume. Fully enclosed for printing high-temperature materials like ABS and ASA. AI-powered LiDAR and a built-in camera help detect errors.

- Cons: Software is still maturing compared to more established players. Can be loud at top speeds.

- Best for: Cosplayers making helmets and armor, engineers printing large prototypes, and anyone who feels limited by standard-sized printers.

4. The High-Detail Specialist: Elegoo Saturn 4 Ultra (Resin)

For those who need flawless detail, the latest resin printers are mind-blowing. The Elegoo Saturn 4 Ultra leads the pack with its incredible resolution.

- Type: MSLA Resin

- Pros: A stunning 12K monochrome screen produces details invisible to the naked eye. Features like auto-leveling and an integrated air purifier make the resin printing experience much more user-friendly.

- Cons: Resin printing is a messy process that requires a dedicated, well-ventilated space and safety precautions.

- Best for: Tabletop gamers, jewelry designers, and character artists who demand the absolute best in surface finish and detail.

5. The Prosumer Powerhouse: UltiMaker Factor 4

Bridging the gap between hobbyist machines and industrial giants, the UltiMaker Factor 4 is a professional tool for small businesses and engineers.

- Type: FDM

- Pros: Independent Dual Extrusion (IDEX) allows for printing with two materials or colors simultaneously. High-temperature hotend can handle engineering-grade materials like carbon fiber composites. Unmatched reliability and professional support.

- Cons: A significant price investment.

- Best for: Small businesses, design studios, and engineers who need to create professional-grade functional prototypes with complex materials.

Common First-Timer Mistakes in 3D Printing

- Ignoring Bed Leveling: An unlevel bed is the cause of 90% of print failures. Even with auto-leveling, it’s crucial to understand the process.

- Using “Wet” Filament: FDM filament absorbs moisture from the air, which turns to steam in the hotend and ruins prints. Store your filament in a dry box.

- Forgetting Resin Safety: Resin and its fumes are toxic. Always wear nitrile gloves and safety glasses, and work in a well-ventilated area.

- Not Updating Firmware: Like any smart device, 3D printers need updates. For a deep dive, learn What is Printer Firmware and Do You Really Need to Update It?, as the principles apply to all types of printers.

Frequently Asked Questions (FAQs)

1. How much does a good beginner 3D printer cost in 2025? The entry point for a fantastic, user-friendly FDM printer like the Bambu Lab A1 Mini or a Creality Ender 3 V3 is between ₹25,000 and ₹40,000.

2. Is 3D printing hard to learn? The technology has become much easier in recent years. With modern machines, you can get great prints within an hour of opening the box. Mastering the craft, however, is a rewarding journey that takes patience.

3. What software do I need for 3D printing? You need a “slicer.” This software converts a 3D model (an STL or 3MF file) into instructions for the printer. Popular free options include Cura, PrusaSlicer, and OrcaSlicer.

4. Can I make money with a 3D printer? Absolutely. Many people run successful businesses selling custom prints on platforms like Etsy, providing rapid prototyping services for local businesses, or designing and selling their own models.

Conclusion

The world of additive manufacturing in 2025 is more exciting and accessible than ever. The barrier to entry has been lowered, while the ceiling for creativity continues to rise. Whether you choose a speedy FDM workhorse to build functional parts or a high-resolution resin machine to create works of art, the best 3D printer is the one that empowers you to bring your unique vision to life.

The journey from a simple idea to a solid object you can hold in your hand is an incredible one. Do your research, pick the right tool for your goals, and most importantly, have fun creating. The possibilities are truly limitless.

Unlock Picture-Perfect Memories: The 5 Best Photo Printers 2025 Read More.